Centerboard pivot hole

-

BrianW

- Deckhand

- Posts: 25

- Joined: Mon Aug 27, 2012 10:24 am

- Sailboat: MacGregor 26X

- Location: Westminster, CO

Centerboard pivot hole

I removed my centerboard to do some repair. I had read once that the hole for the pin should be a little bigger to allow relief of stress on the pin. Anyone know if this is true? Or would it be a good idea to put a sleeve in to slow the wear down.

- Cougar

- Engineer

- Posts: 161

- Joined: Mon Jan 12, 2015 3:02 am

- Sailboat: MacGregor 26X

- Location: Leeuwarden, Netherlands

Re: Centerboard pivot hole

Go for the sleeve. I will probably do that myself once I'm finally able to access my centerboard. A stainless pin in a stainless sleeve will outlast the boat.

- sailboatmike

- Admiral

- Posts: 1597

- Joined: Thu Mar 12, 2015 10:17 pm

- Sailboat: MacGregor 26X

- Location: Australia

Re: Centerboard pivot hole

A stainless steel pin in a stainless steel bush will bind, NEVER have stainless to stainless contact in the way of a bush and a pin, it can get very nasty.Cougar wrote:Go for the sleeve. I will probably do that myself once I'm finally able to access my centerboard. A stainless pin in a stainless sleeve will outlast the boat.

Also dont use stainless below the water line if the boat lives in the water, the crevice corrosion will eat away the pin as stainless requires oxidization the form is protective layer, you wont see the corrosion unit your keel falls out

Have look at this and you will never use stainless in a situations that air cant get to it again

http://forum.woodenboat.com/showthread. ... eel-screws

If your boat does not live in the water use a bronze bush and a stainless pin

- Cougar

- Engineer

- Posts: 161

- Joined: Mon Jan 12, 2015 3:02 am

- Sailboat: MacGregor 26X

- Location: Leeuwarden, Netherlands

Re: Centerboard pivot hole

Is that so? I suppose if the contact is limited by using a rather wide sleeve, binding wouldn't be very likely to occur. Also, isn't binding the result of excessive heat build up?sailboatmike wrote:

A stainless steel pin in a stainless steel bush will bind, NEVER have stainless to stainless contact in the way of a bush and a pin, it can get very nasty.

Please do correct me if I'm wrong.

Re: Centerboard pivot hole

Galling (binding) is from heat. However the heat could be generated from droping or raising the center board if there is enough pressure on it. A bronze or nylon bushing would be better suited for this task. One more thing to think about when you are re-enginer The center board. The pivot is generaly not designed to withstand 100% of the load. The center board wedges in the trunk that takes most of the load. I did change mine like you want. I am just using a good fibergass hole with a epoxy teflon coating. (Same as my bottom paint). I did rebuild the top of the center board and the trunk to square everything up to where there is 0 slop. After that I added some lead to it to make sure it did not hang up. Then added a 2 to 1 uphaul to compinsate for the heavier board. Have been running like that for over 5 years with no issues. Still with the centerboard down there is 0 banging at anchor and it goes up and down with no issues.Cougar wrote:Is that so? I suppose if the contact is limited by using a rather wide sleeve, binding wouldn't be very likely to occur. Also, isn't binding the result of excessive heat build up?sailboatmike wrote:

A stainless steel pin in a stainless steel bush will bind, NEVER have stainless to stainless contact in the way of a bush and a pin, it can get very nasty.

Please do correct me if I'm wrong.

- sailboatmike

- Admiral

- Posts: 1597

- Joined: Thu Mar 12, 2015 10:17 pm

- Sailboat: MacGregor 26X

- Location: Australia

Re: Centerboard pivot hole

This phenomenon is known as galling and it is most prevalent with intermittently operated, slowly sliding surfaces. It is caused by cold welding of the high points of

clean, oxide free metal left when the oxide film is dislodged by surfaces rubbing against each other.

From the article Galling And Its Control

clean, oxide free metal left when the oxide film is dislodged by surfaces rubbing against each other.

From the article Galling And Its Control

- BOAT

- Admiral

- Posts: 4969

- Joined: Fri Oct 19, 2012 5:12 pm

- Sailboat: MacGregor 26M

- Location: Oceanside, CA MACMJ213 2013 ETEC60

Re: Centerboard pivot hole

All the trailer boats I had before the M had a swing centerboard or a swing keel - in all cases the pin would rot off. I remember one time we could not get a Cal Jensen off the trailer because the pin broke just as we were launching. I think the old venture boats all had fiberglass keels and many people in the early days would put a "keel lock" on the boats because in the early days there was fear that if the boat turned turtle in heavy seas the swing keel would swing right thru the bottom of the boat when the boat was upside down.

The "keel lock" never really caught on as a safety device but the people I spoke to who had it said it decreased the wear on their pivot pin by a factor of 10!! That seemed like a good enough reason toe secure the keel in the down position.

The best swing set up I had was the all metal swing centerboard in the A23 - it was all steel and never corroded and was so loose and floppy it never binded up (sure was a noisy thing). The worst was the swing keel in the Balboa 26 and the Cal Jensen 25 Flush Deck - we saw one drop it's keel completely on the way to Catalina once and we helped the tow boat that brought it back. What a mess. If your in calm sea you will have no problems, but if you go in heavy seas I don't think mixing stainless and ferrous metals is a great idea - the stainless will deform the ferrous metals even though the ferrous metals will not fail first - the stainless will. It's a mess, there is no way to really fix the issue.

Well, there is one fix, eliminate all the metal with an un-weighted all plastic daggerboard that can't harm the boat in any weather or wave - but hey - that's a different boat so forget that idea.

I would use all brass but it would need to be replaced often as it would deform quickly.

The "keel lock" never really caught on as a safety device but the people I spoke to who had it said it decreased the wear on their pivot pin by a factor of 10!! That seemed like a good enough reason toe secure the keel in the down position.

The best swing set up I had was the all metal swing centerboard in the A23 - it was all steel and never corroded and was so loose and floppy it never binded up (sure was a noisy thing). The worst was the swing keel in the Balboa 26 and the Cal Jensen 25 Flush Deck - we saw one drop it's keel completely on the way to Catalina once and we helped the tow boat that brought it back. What a mess. If your in calm sea you will have no problems, but if you go in heavy seas I don't think mixing stainless and ferrous metals is a great idea - the stainless will deform the ferrous metals even though the ferrous metals will not fail first - the stainless will. It's a mess, there is no way to really fix the issue.

Well, there is one fix, eliminate all the metal with an un-weighted all plastic daggerboard that can't harm the boat in any weather or wave - but hey - that's a different boat so forget that idea.

I would use all brass but it would need to be replaced often as it would deform quickly.

- sailboatmike

- Admiral

- Posts: 1597

- Joined: Thu Mar 12, 2015 10:17 pm

- Sailboat: MacGregor 26X

- Location: Australia

Re: Centerboard pivot hole

I would think that a mild steel bolt that has been "gun blued" (heated with a blow torch and quenched in oil) running through a nylon bush would be good cheap and long lasting solution, but what it comes down too is nothing beats regular inspection.

By regular I would think every 5 years or so depending on the size of the bolt

By regular I would think every 5 years or so depending on the size of the bolt

- Newell

- First Officer

- Posts: 439

- Joined: Sat Feb 07, 2004 1:42 pm

- Sailboat: MacGregor 26X

- Location: Layton, Utah, 96X Fast Sunday, 89D Windancer

Re: Centerboard pivot hole

I just 2 months ago removed my CB on Fast Sunday and re-checked the work on the pivot pin upgrade I did @ 18 years ago. I had

put a brass pipe bushing (Lowes) 1/2" pipe, added washers to both sides of the pin/board and capped the ends of the pin with rubber caps. Widened the top of the board with FG and matting to within 1/8" of width of CB well. It has been a great upgrade mod and the inspection found no problems with the pin/bushing area.

My CB is silent at anchor.

put a brass pipe bushing (Lowes) 1/2" pipe, added washers to both sides of the pin/board and capped the ends of the pin with rubber caps. Widened the top of the board with FG and matting to within 1/8" of width of CB well. It has been a great upgrade mod and the inspection found no problems with the pin/bushing area.

My CB is silent at anchor.

- Bilgemaster

- First Officer

- Posts: 467

- Joined: Sun Apr 26, 2015 5:03 pm

- Sailboat: MacGregor 26X

- Location: Woodbridge, Virginia--"Breakin' Wind" 2001 26X, Honda BF50A 50hp engine

Re: Centerboard pivot hole

I'm glad this topic came up. I sifted through several threads of the archives for items on "centerboard banging" and "clunking" and the like, and from what I gather, it seems to be a pretty common issue in stock 26X setups (which I presume mine to be), yes? I have often noticed on my 2001 26X that when I heave to in order to go below for a bit that there's sometimes a sort of low clunking that one hears especially well in the cabin. I assume this must be the centerboard slopping around on its pivot. Barring some modification of the pivot point, a bit of this "clunking" is actually normal, right? But even if so, how could one determine on the trailer or perhaps in some shallows at anchor, when such clunking is BEYOND normal, and needs attention? Is there a certain amount of allowable side-to-side play or something, beyond which the pivot point should be serviced or replaced?

When I first got my 26X it was a real waiting game to let her centerboard down. It might take several minutes to fall fully downward. She had probably been sitting on her trailer for about 5 years, and, judging by the state of her ablative bottom paint, before that had most likely spent at least a season or three in the water. So, was probably pretty stiff as a result. After a bit of scrubbing around in that hull recess with a long thin brush and with a can or so of silicone spray shot down into the haul line hole on deck and up around the pivot point from below, she has eased up quite a bit, and the more I use her, the easier it has become to raise and lower.

Still, I'd like to see some definitive guide or explanation on the assessment, maintenance or repair of this part of the boat. Is there some previous forum posting or mod feature that one should particularly look over? Maybe a YouTube video on the matter?

When I first got my 26X it was a real waiting game to let her centerboard down. It might take several minutes to fall fully downward. She had probably been sitting on her trailer for about 5 years, and, judging by the state of her ablative bottom paint, before that had most likely spent at least a season or three in the water. So, was probably pretty stiff as a result. After a bit of scrubbing around in that hull recess with a long thin brush and with a can or so of silicone spray shot down into the haul line hole on deck and up around the pivot point from below, she has eased up quite a bit, and the more I use her, the easier it has become to raise and lower.

Still, I'd like to see some definitive guide or explanation on the assessment, maintenance or repair of this part of the boat. Is there some previous forum posting or mod feature that one should particularly look over? Maybe a YouTube video on the matter?

- Newell

- First Officer

- Posts: 439

- Joined: Sat Feb 07, 2004 1:42 pm

- Sailboat: MacGregor 26X

- Location: Layton, Utah, 96X Fast Sunday, 89D Windancer

Re: Centerboard pivot hole

The guide for acceptable slop and

noise from your CB is whether you can sleep with the noise or not

noise from your CB is whether you can sleep with the noise or not

- Bilgemaster

- First Officer

- Posts: 467

- Joined: Sun Apr 26, 2015 5:03 pm

- Sailboat: MacGregor 26X

- Location: Woodbridge, Virginia--"Breakin' Wind" 2001 26X, Honda BF50A 50hp engine

Re: Centerboard pivot hole

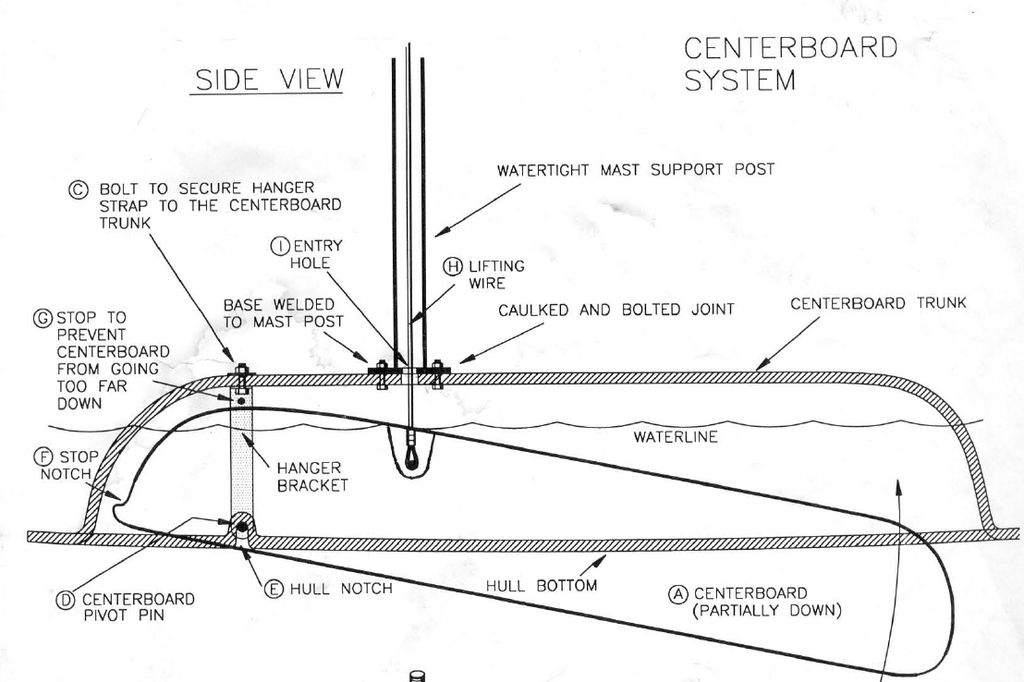

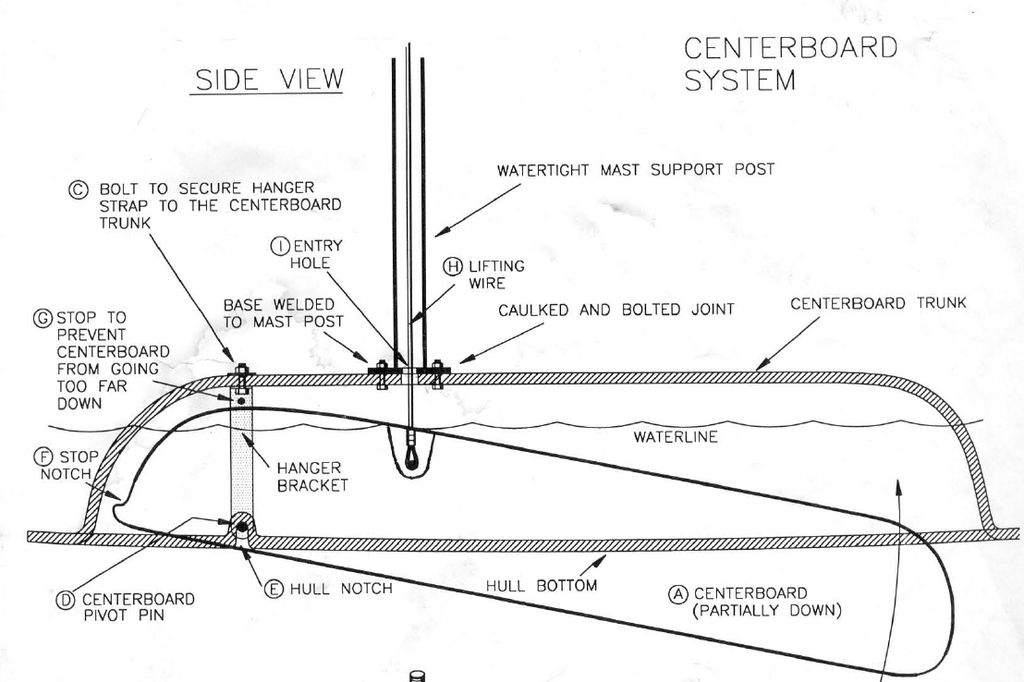

So, I went by the boatyard today, and here's a shot of one side of a through-pin where the swing keel pivots in a sort of recess in the hull. Turns out it's called a "Pivot Pin". The other side of this pin looks similar.

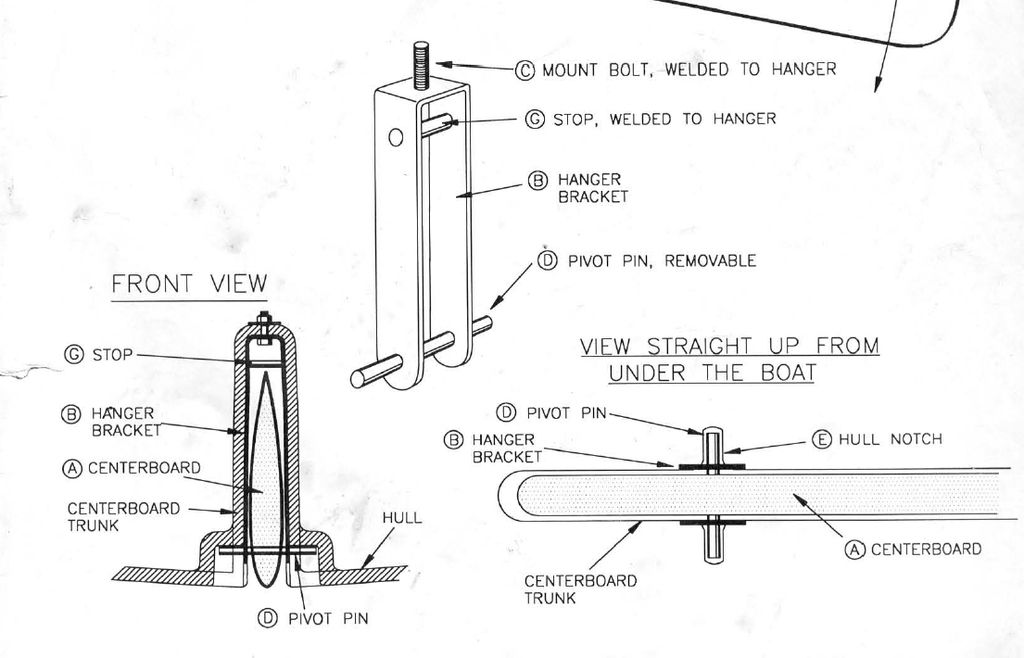

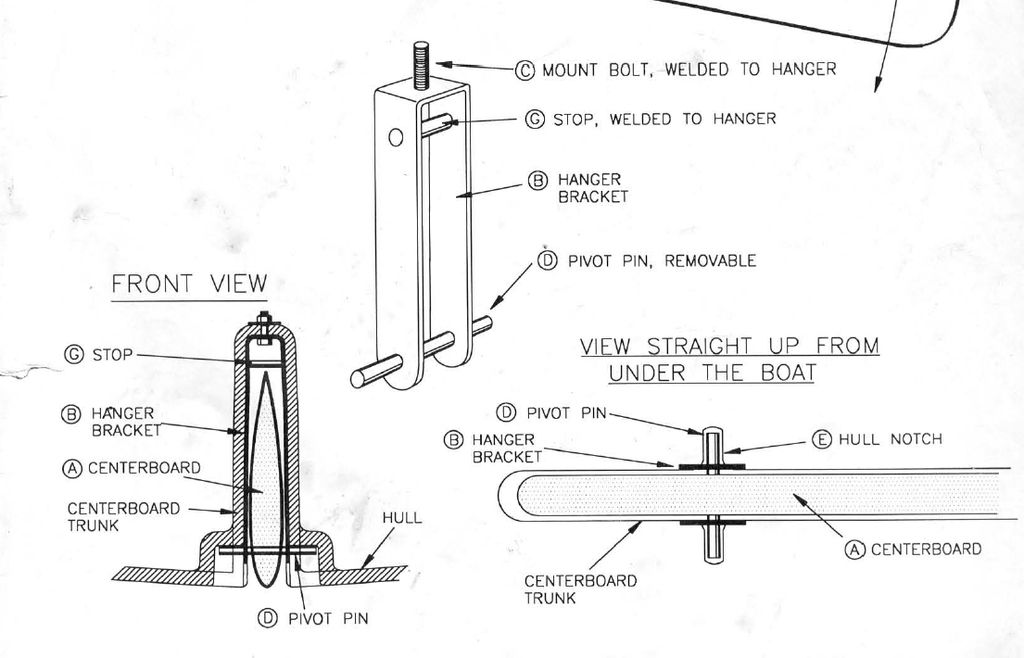

Unless I am misinterpreting these drawings from the factory manual, I seem to be completely lacking that "Hanger Bracket" (B), so that would explain all that clunking around. It's a wonder the swing keel's still in one piece or even attached to the boat.

Guess I'll be contorting myself and digging around in the bilge soon...Oh happy day!

Unless I am misinterpreting these drawings from the factory manual, I seem to be completely lacking that "Hanger Bracket" (B), so that would explain all that clunking around. It's a wonder the swing keel's still in one piece or even attached to the boat.

Guess I'll be contorting myself and digging around in the bilge soon...Oh happy day!

- Cougar

- Engineer

- Posts: 161

- Joined: Mon Jan 12, 2015 3:02 am

- Sailboat: MacGregor 26X

- Location: Leeuwarden, Netherlands

Re: Centerboard pivot hole

You're not lacking anything. The bracket is clearly there in the picture...Best wishes BTW!

- Bilgemaster

- First Officer

- Posts: 467

- Joined: Sun Apr 26, 2015 5:03 pm

- Sailboat: MacGregor 26X

- Location: Woodbridge, Virginia--"Breakin' Wind" 2001 26X, Honda BF50A 50hp engine

Re: Centerboard pivot hole

Well, thank God for that! I thought that black thing was some sort of big round spacer-grommet or shim or something, but now that I really look closely at all the pictures I took, some with the benefit of a bit of auto-flash, I see it goes right up there into the trunk towards the cabin. Today's lesson learned: Next time I crawl under there for another impromptu bottom paint touchup, inspection tour, or barnacle hunt, definitely bring a damned flashlight, and also: the big round spacer-grommet is me!Cougar wrote:You're not lacking anything. The bracket is clearly there in the picture...Best wishes BTW!

Just for the record, here are all three shots. In the 2nd you can really see the black thing goes up towards the cabin:

- BOAT

- Admiral

- Posts: 4969

- Joined: Fri Oct 19, 2012 5:12 pm

- Sailboat: MacGregor 26M

- Location: Oceanside, CA MACMJ213 2013 ETEC60

Re: Centerboard pivot hole

I now see why Roger was so obsessed with creating a board with no metal parts.