As for thickness, I used 1/2" thick oak-sided plywood for the main part of the table. Underneath I used 3/4" thick ribs made from pine and Gorilla-glued and screwed with brass screws. I always use brass on boats to avoid corrosion. The combined parts make for a very strong, but reasonably lightweight table. You don't need 3/4" thick plywood - it's overkill IMHO.Divecoz wrote:Kevin did you manage to buy that Outside Oak Corner or did you have to make it..???

IF? We used 3/4" or better yet 1" Oak Faced Plywood and Veneered the two corners? Reduced the depth of the Front pull drawers and there by allowed 1 back and 1 middle rib , Might that be strong enough to support a persons weight?

Hummm I have 1 piece of 3/4" maple for another project I am working on in the house. Maybe tomorrow I set up some blocks and see if it will hold my weight.. The Spans not that big humm maybe?

Not sure what you mean by "outside oak corner", but let me see if I can help... the edging I used to make the 'lip' was some of this stuff, in oak:

Lengths were cut and the ends rounded to suit. I then applied the strips with wood glue and some small brass pin-nails that were later sunk with a nail set and filled so to be invisible. Once it was all dry I shaved off the overhanging remainder of the "L" channels off the bottom of the table and sanded to finish.

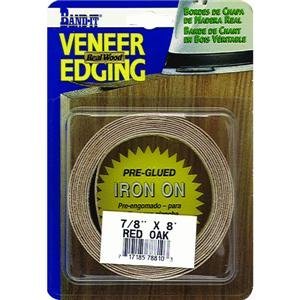

As for the actual round corner edges of the table, before applying the "L" channels I applied some oak veneer banding to cover the end-grain of the oak plywood... like this stuff: