That block of wood is an accurate rendition of the relevant part of my

Now to find a stainless steel bender...

Yeah, I'm in talks with one or two.Boblee wrote:Any metal fabrication shop should be able to bend it for you but personally would just do it in a vice with a hammer.

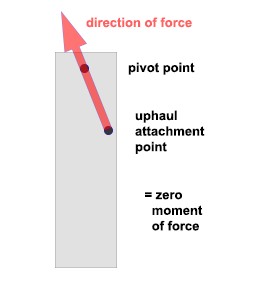

Better leverage in lifting them, esp. while underway (sail > power)Boblee wrote:BTW what are you trying to accomplish with the lever?

Thanks. I will check them out.seahouse wrote:Looks good Dave. I've dealt with Bayview Metals (I think they're up your way) in the past with stainless fabrication.

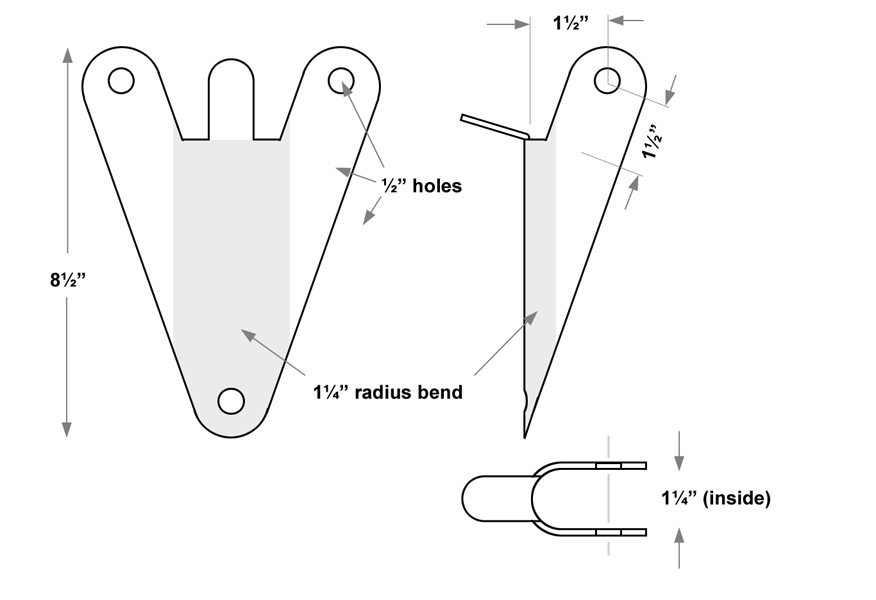

Thanks! That's precisely what I'm grappling with right now. If I give them flat dimensions and expect them to bend into a 3D form, I have to know the thickness of the material as well as how it compresses/expands when it bends - or my final piece will come up short. Your explanation is exactly what I need to know (and my intuition, as someone who was never in the biz, is correct).seahouse wrote:I'm a little rusty, but I used to do cold bend calculations regularly. During a bend, half the thickness of the metal "compresses" (the inside) and the other half stretches (the outside). Except it's not half. It's about 40% of the thickness of the material, closer to the inside, where the "neutral" bend line is, which is where the metal neither stretches nor "compresses". (Note the quotes).

D'oh. Of course.seahouse wrote: BTW - your bend radius will be 5/8" for an inside 1- 1/4". (a typo).

Yep they come up easy peasy on theHighlander wrote:Why not just add a few cheep blocks & make a 2-1 or even a 3-1 pulley system

J

Because 2 x zero or 3 x zero is still zero.Highlander wrote:Why not just add a few cheep blocks & make a 2-1 or even a 3-1 pulley system

J

That is no problem at all. Once the rudders are above horizontal, there is no further need for mechanical advantage. The lifting "vector" is plenty far from the pivot point by then.seahouse wrote:Yes, I agree, J.

The advantage of the blocks you're suggesting is that the force-multiplying happens throughout the uphaul arc. With the levers we're discussing however, you gradually lose the mechanical advantage as the rudder moves through the arc as it is raised, as it eventually becomes zero.

B.

Yes. Thing is, because the tab probably will bend under load, there will likely end up being very little pressure on the middle or end of the tab; it will all be concentrated at the base (i.e. even if the tab were of zero length, it would likely still function). So I think it's strong enough to hold. My bigger concern is whether it digs into my rudder at that point.Paulieb wrote:That looks like a really cool idea. Nice diagrams too.

My only recommendation would be that the Tab that looks like it will rest up against the rudder when pulled up, looks like it might be a weak point.

I would consider adding a wedge shaped gusset to strengthen that point - there is likely to be a lot of stress there and metal fatigue.

Paul