Page 1 of 3

basic engineering help/input needed please

Posted: Sat Mar 01, 2014 11:51 am

by Wayne nicol

hi all.

i am going to be building a set of davits for my

my intention is to make the davits interchangeable with a rack that will hold my cooler for when we are dedicated fishing

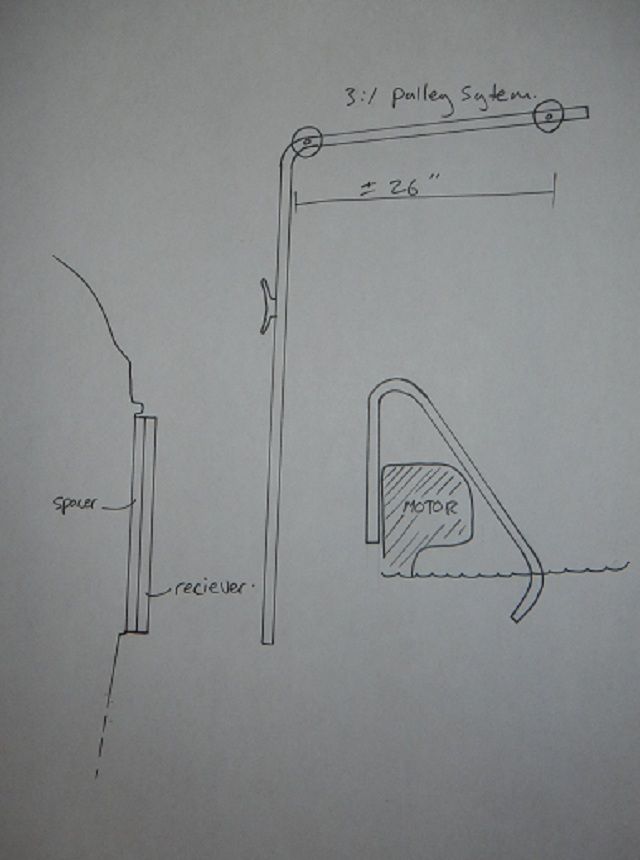

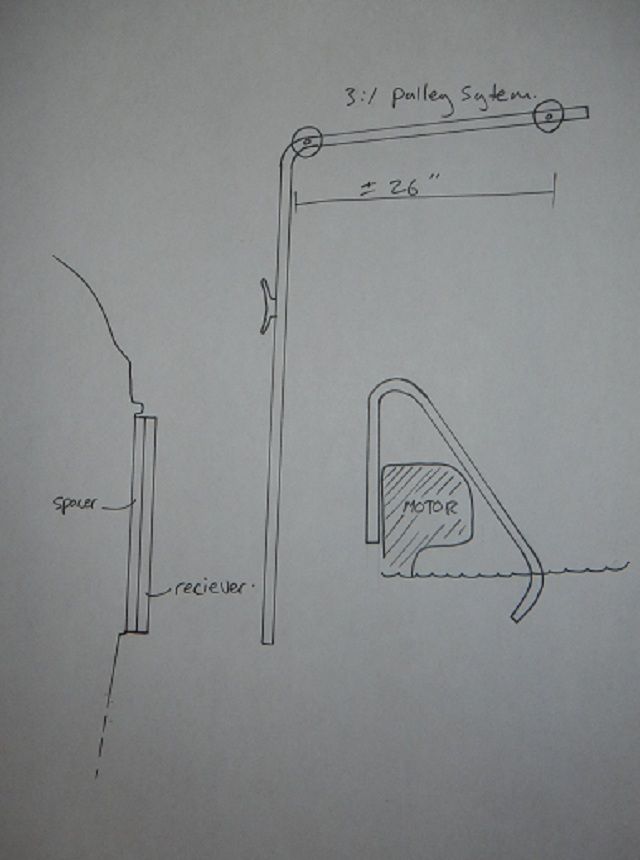

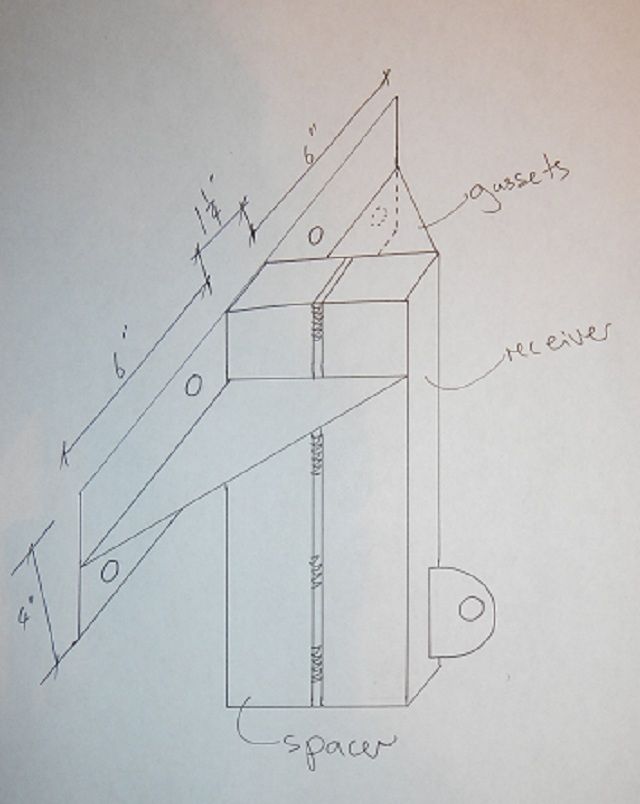

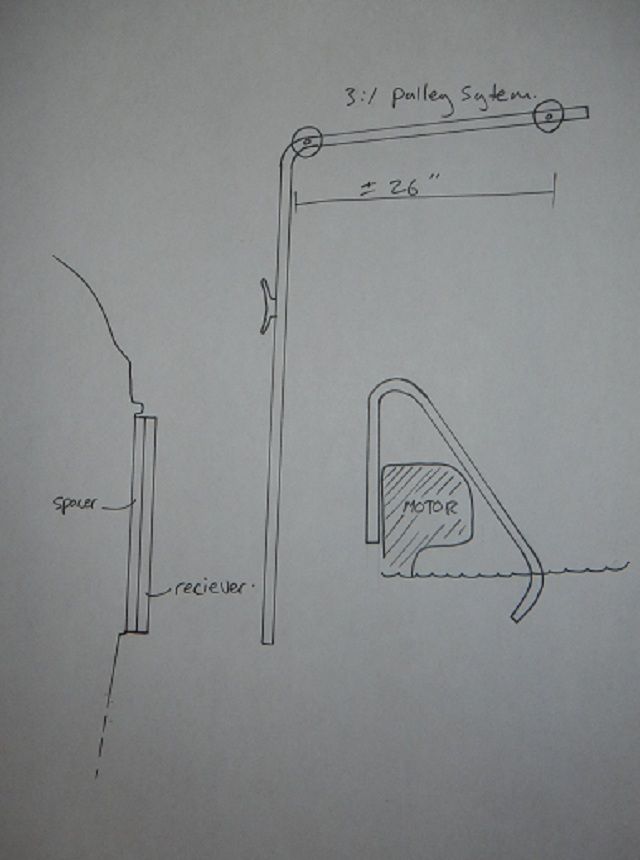

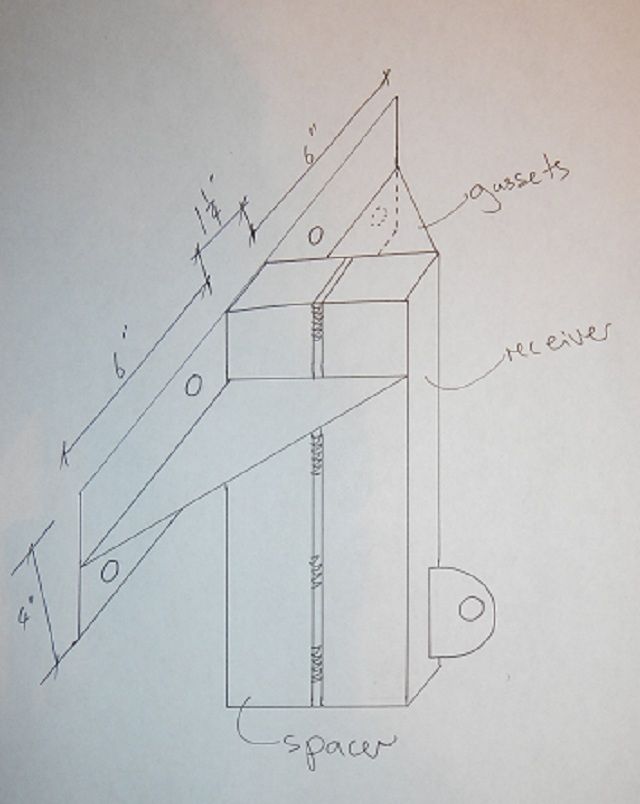

here are some very rough sketches

the dingy is probably going to be one of the walker bay 8's

affordable, and robust, and the "kids" could sail it too

and it will handle our rocky/barnacled shores better than the inflatable- not that i am going to smash it up though!!

when we are dedicated fishing, the inflatable on the fore deck, cooler on the rack.

so the question is this...

what size s/s should i be using for the davits,i would think a square profile would be better, would allow for a better attachment of spacer and brackets for attachment to the transom. i dont have a problem bending the sq. tube. i have made benders before to bend sq. tube.

i will make the reciever as long as possible- and yes- it will stay above the waterline!

i guess the davit will extend about 2.5' above the reciever bracket, and extend out another 2.5' , or a little less, to hold the walker( a little extra space for a gusset in the bend!- but maybe an external type "gusset" to keep the dink as close to the boat as possible to reduce leverage).

i would like the simplicity of a single strut build, and not a truss structure- total weight on the davits would be about #100-( boat + oars + cover + the guard brackets used to protect the motor/rudders during deployment/retrieval - obviously both motor and rudders down for this )

so that equates to about #50 per arm

i have thought long and hard about the pros and cons of this, the leverage that extra weight will have sticking out the back of the boat, but i wont ever have stern rail seats on it, so i guess that eliminates #300 plus of weight over the stern there!

i will still always have the option of towing the dink if need be!

any ideas, input etc!

feedback on s/s size?

many thanks all

Re: basic engineering help/input needed please

Posted: Sat Mar 01, 2014 2:17 pm

by Nautek

Good project

Thinking of doing the same myself

I was going to use 11/4" round tube

You could go 1" i would think but will need a lot more bracing

Looking forward to some photos when built

Allan

Re: basic engineering help/input needed please

Posted: Mon Mar 03, 2014 6:29 am

by Tomfoolery

1" x .068" wall square tube has a section modulus of .074 in^3. The bending moment in either arm, at the bend, using your figure of 50 lb, centered between the sheaves (about 13" out), is 650 lb-in. That makes the bending stress about 8780 psi (8.8 ksi, or kilopounds (kips) per square inch - it's easier to think in terms of ksi when doing structural work). The yield strength of common SS is somewhere around 30 ksi or so, which makes a factor of safety (on bending) of around 3.4:1.

BUT, that does NOT take into account any dynamics (swinging dink), material flaws, changes in material properties due to bending, local buckling (especially at the bend), someone hanging on it, or the boat getting caught on something, etc. Welding to it also puts potentially high local stresses in small areas, so I would try to avoid welding.

It also says nothing about stiffness, though my gut tells me it's not going to be much given the geometry, and flex is not a bad thing unless there are reasons for containing it.

The bending moment will be a little higher, with stresses to match, where it comes out of the pocket due to the slightly greater moment are (transom is angled a little), but again, that's where judgment comes in. But in this case, you can build it and test it, and reinforce it only if you think you need it. I'd try to stay away from welded gussets if possible.

Oh, and put holes where you've shown the sheave centers, in the middle of the webs (vertical faces), not top/bottom, at least for the one at the bend, as you'll lose a very significant portion of the strength there. The vertical faces carry shear primarily, and taking out some metal there won't do much.

Also consider side loading, like when the dink sways side to side (relative to the Mac centerline), as that'll put some twist and side loading into the davits. The mounts are probably going to see the most undesirable loading from that, unless you weld on some wide mounting plates. Think of the 1" square tube being twisted - lotta 'leverage' there, but flat plates with a bolt on each side (as viewed from behind) will greatly reduce the reaction forces.

Re: basic engineering help/input needed please

Posted: Mon Mar 03, 2014 9:17 am

by RobertB

What struck me most about your design is that it does not spread out the loads on the boat. All the support is essentially a torsion loading on a stern bracket and this can be pretty brutal to a somewhat flexible structure. Look at other boat davits or similar items. They usually have some kind of bracing that simplifies the loading on any particular area. As far as the actual davit structure, I would encourage you to adopt a braced kind or structure versus one dependent upon the strength of a particular member. Use triangles. Remember, the load you are designing for is not the weight of a tender or a cooler, it is also the additional weight of a person hanging onto either, the weight of everything in the cooler, and the dynamic loads. Plus a factor of safety of at least three, but since this could be considered an overhead lifting device, a factor of safety of five is more appropriate.

So, to illustrate: 50 pound per arm basic loading, plus 200 pounds if a person grabs onto the arm = 250 pounds. Apply a factor of safety of 5 and you have an arm that should be able to hold 1250 pounds before failure (and you could also consider dynamic loading due to movement). The simple bend without bracing has little chance of being anywhere strong enough.

Re: basic engineering help/input needed please

Posted: Mon Mar 03, 2014 9:31 am

by Wayne nicol

Great, thank you sir!!

thats just what i need- some real knowledge- instead of the school of trial and error

.

i had planned on some wide monting brackets- hear you on the torque there.would probably be prudent to really snug the dink up real tight so that there was no swinging/movement.

thanks for the info with regards to sheave mounting hole placement.

i hear you on the welding- will refrain from that!.

my initial thoughts were to use a 1.25" square s/s

what wall thickness would you recommend and what quality of s/s would be the best

.

many many thanks

wayne

Re: basic engineering help/input needed please

Posted: Mon Mar 03, 2014 9:39 am

by Wayne nicol

thanks RobertB

was typing my response to Tomfoolery, then only saw yours.

those sketches are just concept drawings- certinally not a design drawing. i had planned on substantial backing plates and gussets from the reciever tube back to the backing plates, and also substantial internal backing plates too, but any advice or input is greatly appreciated and needed.

the dingy and its gear weighs about #100.

but the cooler would be substantially higher- with a load of fish, probably #250.

it will of course not be raised and extended away from the transom, like the davits, and some of the load would actually be inboard of the reciever tube.

i see you mention more of a truss type structure for the actual davits, any ideas on this and how it would attach to the boat.

the sketches are not cast in stone- i am more than happy to follow a better route if need be!!

many thanks all

wayne

Re: basic engineering help/input needed please

Posted: Mon Mar 03, 2014 11:47 am

by Tomfoolery

Wayne nicol wrote:<snip> i hear you on the welding- will refrain from that!.

My comments about welding have to be taken in the context of your capabilities. If you're not good at it, or if the metal is too thin, or if a myriad of other unknowns come into play, then I would suggest staying away from it. If you're good at it, especially thin material, then there's nothing wrong with welding it. I work in heavy steel fabrications, not SS, so I can only apply caveats as I see them, projected from my experience in carbon steel.

Wayne nicol wrote:my initial thoughts were to use a 1.25" square s/s

what wall thickness would you recommend and what quality of s/s would be the best

.

.Thinnest you can source, which is probably .065", which will be about 50% stronger than the 1" x .065 square tube. If you use 316 SS (ASTM A554), the bending strength will be about twice as much as 304 (around 60 ksi, with an ultimate tensile around 90 ksi), so the total strength in bending, given the same geometry, will be over 3 times as much, for a factor of safety (or more like a factor of uncertainty) of over 10:1 on bending.

But 250 lb applied at the end of just one arm puts the bending stress up near the yield, at the bend, and everywhere down the near-vertical leg, and when it deflects outward, a hanging load will move farther away from the boat, increasing the bending stress in the near-vertical leg. So while it's pretty robust for what it's intended to support, do be aware that if you try hard enough, you can still bend them.

And then there's the attachment method to the boat, which is another kettle of fish.

Re: basic engineering help/input needed please

Posted: Mon Mar 03, 2014 11:55 am

by Wayne nicol

gotcha...

so what are your thoughts on attaching to the transom.

we do have good welders here that can do a good job- but i would also be happy to stay away from it if need be.

any particular radius for the bend, that will be better or worse.

i was thinking a big top plate and bottom plate- extending out either side a good 6"x 4" with two bolts per side, top. and again for the bottom, with substantial( larger than outside plates) backing plates

maybe a mid plate needed too??- no load - except twisting?

thanks

wayne

Re: basic engineering help/input needed please

Posted: Mon Mar 03, 2014 12:18 pm

by Tomfoolery

I can't visualize it. Do you have a sketch of what you're thinking?

Re: basic engineering help/input needed please

Posted: Mon Mar 03, 2014 1:12 pm

by Nautek

Maybe the engineers amongst us can do up a suitable design so that we can all use it

I have been wanting to do davits for a long time

At my age pulling a dink up onto the front deck by myself is a bit difficult

Allan

Re: basic engineering help/input needed please

Posted: Mon Mar 03, 2014 3:57 pm

by Wayne nicol

hear hear Allan.

the thing i hate about the dink up forrard is that it covers the anchor locker partially. and i need the space for my crab and prawn traps anyhow!!

i will do a sketch as soon as i get home- sorry i understood it in my little brain just fine- what you cant mind read- you must be married too

thanks fellas- so far!

Re: basic engineering help/input needed please

Posted: Mon Mar 03, 2014 6:15 pm

by Wayne nicol

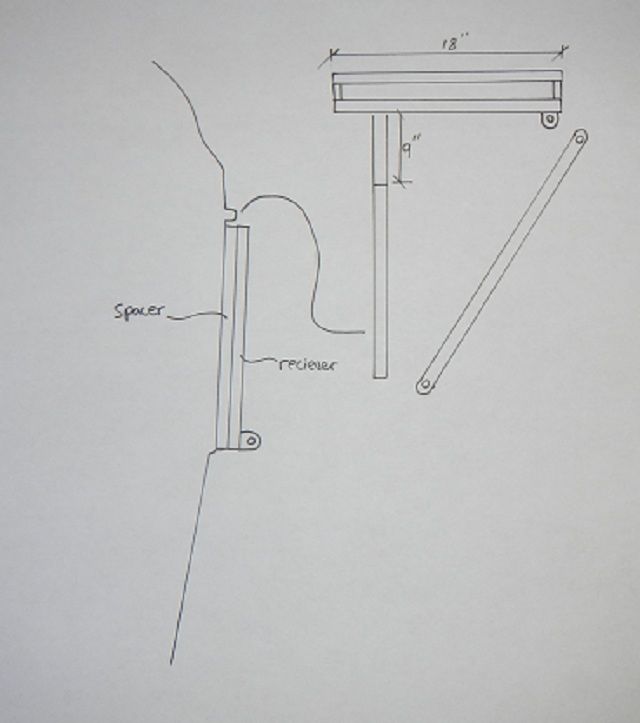

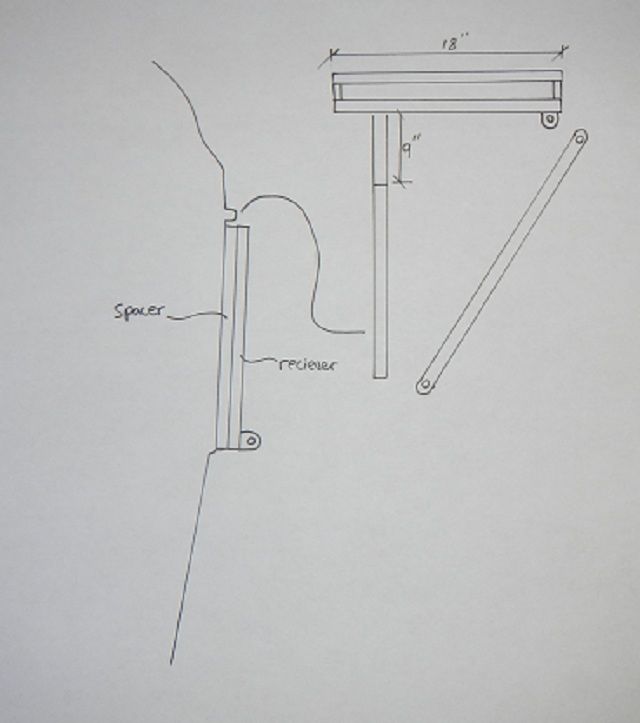

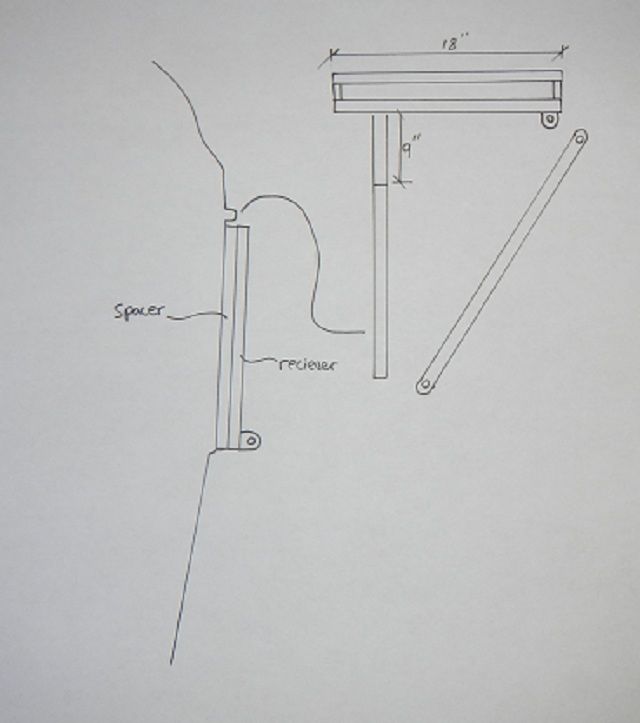

ok heres a quick an' nasty sketch.

a mounting plate like this on the top and bottom of each receiver bracket- one receiver bracket per side

oversize backing plates on the inside

4 bolts per mounting plate - but could up that to 8 per bracket

8 top , 8 bottom, then again another 8 and 8 on the other side

Re: basic engineering help/input needed please

Posted: Tue Mar 04, 2014 12:53 pm

by RobertB

I recommend at least two mounting points per side. A main and a brace - this will distribute the load on the boat - also should eliminate torsion loading. Maybe go walk around a marina and look at how these things are installed on other boats?

Re: basic engineering help/input needed please

Posted: Tue Mar 04, 2014 2:26 pm

by Wayne nicol

yup had planned a mounting point top and bottom of each reciever, but only drew the one.

you think that would work.

problem with the marina deal. we are on an island 60 miles from the mainland- no real marinas here- just working docks- heck we dont have a pumpout station on the entire island!!

there are only a half dozen or so sailboats here, and mine is the only mac of any type!

but maybe i will cruise the net a bit

thanks

wayne

Re: basic engineering help/input needed please

Posted: Tue Mar 04, 2014 2:57 pm

by Tomfoolery

I think you could make those mounts considerably smaller. The mounting flange is the right way to go, but a single bolt on each side should be plenty as long as the flange plate is thick enough to not distort under load. The top ones are going to take most of the twist of the davit arms attempting to rotate, and the bolts will be in tension, with the combination of gravity load and lateral rotation, while the bottom mounts will virtually always be in compression against the hull, and not much more. Maybe lose the diagonals for the bottom ones.

If you wanted to make something more robust, then the top pair would be the ones. The bottom pair will have much lighter loads on them. No need for a continuous socket, like one long one on each side instead of upper and lower. The stuff in the middle won't do anything but add weight.

I think you're on the right track, but the devil is in the details, trite as that may sound.