Rick

Another forestay failure/mast crash

- pokerrick1

- Admiral

- Posts: 2269

- Joined: Sun Aug 27, 2006 7:20 pm

- Sailboat: Venture 23

- Location: Las Vegas, NV (Henderson, near Lake Mead)

Re: Another forestay failure/mast crash

Just glad to see you weren't hurt - - - an old slow guy like you could have been severly injured

Rick

Rick

- Catigale

- Site Admin

- Posts: 10421

- Joined: Fri Jun 11, 2004 5:59 pm

- Sailboat: MacGregor 26X

- Location: Admiral .............Catigale 2002X.......Lots of Harpoon Hobie 16 Skiffs....Island 17

- Contact:

Re: Another forestay failure/mast crash

Perfect sense if you engineer it. The diameter is chosen by the anticipated load and the strength of the attach points - the stays have to be at a certain tension to remove slack. If you make it too big, you have to tension it more, and then a stronger attach point.

Four thicker stays fighting against the one thinner forestay??

What sense does that make?

Flex and corrosion are your enemies here, not tensile strength.

Hardcrab - Im guessing corrosion is the MO here, since you've been diligent about your tension.

- Russ

- Admiral

- Posts: 8374

- Joined: Thu Oct 11, 2007 12:01 pm

- Sailboat: MacGregor 26M

- Location: Bozeman, Montana "Luna Azul" 2008 M 70hp Suzi

Re: Another forestay failure/mast crash

So how does one prevent such events?Catigale wrote:Flex and corrosion are your enemies here, not tensile strength.

Hardcrab - Im guessing corrosion is the MO here, since you've been diligent about your tension.

His layman's inspection showed no problems as I'm sure most of us would. I have no doubt that flex is a major cause of fatigue. But how do we inspect this? Threads like this make me nervous. Every heavy wind makes me worry if my forestay is compromised and I'll find a mast in my lap.

Others have used a spare halyard to the pulpit as a backup. I've been temped to do this but my jib halyard (used for my jib sock) is just below the top of the furler, so it can't be used. Now I'm thinking of running another backup forestay for this purpose.

- seahouse

- Admiral

- Posts: 2182

- Joined: Sun Dec 07, 2008 9:17 pm

- Sailboat: MacGregor 26M

- Location: Niagara at Lake Erie, Ontario. 2011 MacM, 60 hp E-Tec

- Contact:

Re: Another forestay failure/mast crash

Hey Parrothead!by parrothead » Mon Jul 11, 2011 11:53 am

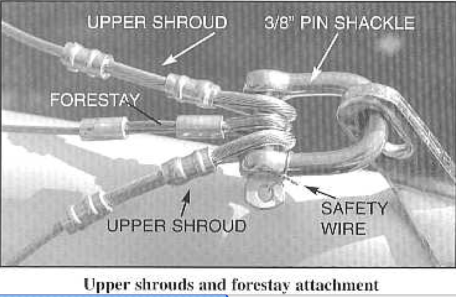

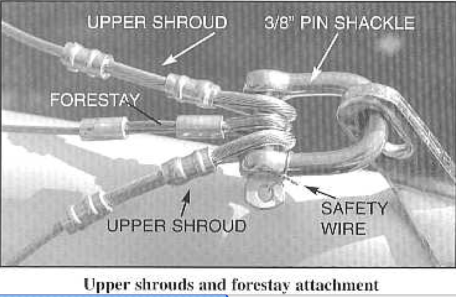

Toggle? What toggle?? Our came with the optional CDI furler, but the upper end of the forestay looks just like the photo in the MacGregor manual - simply a loop in the end of the wire.

Interesting how timely this topic is for me. I also ordered the CDI furler, (May 2011) dealer-supplied and dealer-assembled ("dry commisioning"). I recall seeing exactly what you picture on my mast as well, which I raised, and then read that the CDI manual excludes such a fitting as being inappropriate in favour of the toggle (it's at the back of the manual). I'm not about to miss any sailing over this, but I will confirm my memory when I next lower the mast. Another item for the dealer snag sheet if there's no toggle up there.

Actually this is a very serious issue.

-Brian.

-

DaveC426913

- Admiral

- Posts: 1915

- Joined: Mon Jul 14, 2008 8:05 am

- Sailboat: MacGregor 26X

- Location: Toronto Canada

- Contact:

Re: Another forestay failure/mast crash

Is this something I need to worry about? How do I minimize this?

I guess tuning my standing rigging and checking the forestay regularly is the first step. But apparently even that is not safe.

Anyone point me at instruction to tuning?

- delevi

- Admiral

- Posts: 2184

- Joined: Fri May 06, 2005 1:03 am

- Location: San Francisco Catalina 380, former 26M owner

- Contact:

Re: Another forestay failure/mast crash

Hardcrab,

First, glad to hear nobody got hurt.

I replaced 2 forestays in the past and can confirm there is no toggle, and yes, the CDI manual says you absolutely need one. The OEM forestay is 1/8". The other shrouds are 5/32". I upgraded to 5/32" forestay with a swage attachment vs. the loop... still no toggle though. Upon inspection, I noticed that the wires exiting the swage were broken (roughly half of them.) The issue here is the top of the furler foil. It needs to have some distance from the swage or loop fitting. An inch or two is fine, but sometimes these CDI drums rise. Make sure that's not the case. The other possibility as mentioned is tension. It is difficult to judge forestay tension with the furler over it. Once you set your rake, you control the tension with the upper shroud tension. Get it as tight as you can and can still pin it. I had to crank my mast raising unit pretty hard to be able to pin it. It wasn't easy, but the tension was good. If you do this, you will help prevent future failures and sail better/point higher with the tighter headstay.

BTW, I never felt comfortable with an 1/8" forestay. To my knowledge, no other sailboat of this size uses a 1/8 cable. Not saying this caused the failure, but when in doubt, beef it up.

fair winds,

Leon

First, glad to hear nobody got hurt.

I replaced 2 forestays in the past and can confirm there is no toggle, and yes, the CDI manual says you absolutely need one. The OEM forestay is 1/8". The other shrouds are 5/32". I upgraded to 5/32" forestay with a swage attachment vs. the loop... still no toggle though. Upon inspection, I noticed that the wires exiting the swage were broken (roughly half of them.) The issue here is the top of the furler foil. It needs to have some distance from the swage or loop fitting. An inch or two is fine, but sometimes these CDI drums rise. Make sure that's not the case. The other possibility as mentioned is tension. It is difficult to judge forestay tension with the furler over it. Once you set your rake, you control the tension with the upper shroud tension. Get it as tight as you can and can still pin it. I had to crank my mast raising unit pretty hard to be able to pin it. It wasn't easy, but the tension was good. If you do this, you will help prevent future failures and sail better/point higher with the tighter headstay.

BTW, I never felt comfortable with an 1/8" forestay. To my knowledge, no other sailboat of this size uses a 1/8 cable. Not saying this caused the failure, but when in doubt, beef it up.

fair winds,

Leon

- aya16

- Admiral

- Posts: 1362

- Joined: Fri Feb 18, 2005 6:29 am

- Location: LONG BEACH CALIF Mac M 04 WHITE

Re: Another forestay failure/mast crash

Having seen the break In the wires on Bills boat and the diff in diameter in the fore stay and side stays, the dark color of the broken stay right at the crimp sleeve. My guess is was combo of corrosion/ and the stress from the crimp.

Now Bill was asking about putting a larger diameter stay, with a similar metal crimp, and wanted to know the upside/downside of doing this.

I do too, as Im changing mine before it breaks like bills did.

common sense tells me stronger wire better life, add stronger crimp same metal, no dissimilar metal corrosion problem. Like the cheap aluminum spreaders attached to stainless holders on the mast, the spreaders eat themselves up from the inside out. I would suggest all that have a boat over 3 years old buy and cut themselves some new spreaders from stainless and keep them on the boat for that day the og's fail.

Bills problem does not stem from lack of maintenance, or un called for tension, I know Bill, his boat is maintained and cared for better than any boats I have seen, add to the fact that bills breakage is not the only one that this has happened to, same place same stay. My guess is, its just one more factory minimum that needs to upgraded.

larger wire, and stainless crimps is my guess. any one see that theres is a problem with this? would like to know what doing that up grade would hurt the boat some how, as far as more weight, Ill just put a six pack of beer on board, now, instead of a twelve pack.....and have a stronger stay.

Mike

Now Bill was asking about putting a larger diameter stay, with a similar metal crimp, and wanted to know the upside/downside of doing this.

I do too, as Im changing mine before it breaks like bills did.

common sense tells me stronger wire better life, add stronger crimp same metal, no dissimilar metal corrosion problem. Like the cheap aluminum spreaders attached to stainless holders on the mast, the spreaders eat themselves up from the inside out. I would suggest all that have a boat over 3 years old buy and cut themselves some new spreaders from stainless and keep them on the boat for that day the og's fail.

Bills problem does not stem from lack of maintenance, or un called for tension, I know Bill, his boat is maintained and cared for better than any boats I have seen, add to the fact that bills breakage is not the only one that this has happened to, same place same stay. My guess is, its just one more factory minimum that needs to upgraded.

larger wire, and stainless crimps is my guess. any one see that theres is a problem with this? would like to know what doing that up grade would hurt the boat some how, as far as more weight, Ill just put a six pack of beer on board, now, instead of a twelve pack.....and have a stronger stay.

Mike

- Terry

- Admiral

- Posts: 1487

- Joined: Thu Feb 19, 2004 2:35 pm

- Sailboat: MacGregor 26M

- Location: Vancouver, B.C. Canada. '03 26M - New Yamaha 70

Re: Another forestay failure/mast crash

Ixneigh wrote:The forstays is smaller. I got a replacement from bwy. They confirmed its oem.

Well its total bullcrap. Smaller why? To save wieght? The headstay keeps the mast out of the cockpit. It takes bending and sagging imposed by the jib. It takes wear from tbe jib hanks. It should be the strongest stay on the yacht. Period. Next time my mast goes up it will be replaced. That wire is cheap enough. Replace it every few years.

Forget the friggan chainplates. Larger wire does impose more load on them. It only gives more of a safety margine. Adding extra ballast will impose greater loads.

I may also switch to 7x7 wire. Its less likely to be injured while rigging the boat like 1x19. The latter will NOT tolerate being bent and unbent. Even once near a terminal will ruin 1x19.

Sorry to hear of your mast misadventure. Good luck getting back sailing.

Ixneigh

Yea I was pretty lost on that 1/8 forestay too, and I agree with all the others who say upgrade the wire, but I took it one step further. I had to upgrade to 5/32 forestay to accommdate a Schaefer Snapfurler that rquired a thicker forestay and the rigger suggested I also upgrade from the 1/4 turnbuckle to a 5/16 turnbuckle so I did. Now I carry around a spare oem forestay and turnbuckle but I have a much more robust and safe forestay, gives me peace of mind. I believe there are now enough reported failures to justify the upgrade. The wire & turnbuckle cost $100.00, an easily justified expense. A new mast is going to cost a fair bit if it happens again and that gets damaged, do yourself a favour and upgrade that forestay Hardcrab. With the CDI furler you should have a spare headsail halyard to pin on the pulpit somewhere for a backup. I have a spinnaker halyard that I use when not flying a spinnaker so if I do have a failure it will be in light air while flying a spinnaker.Hardcrab wrote:And does it look like the pictured forestay is a smaller diameter than the upper/lowers to anyone else???

I guess haven't paid that much attention to the whole thing until we almost wore the mast on our heads.

Four thicker stays fighting against the one thinner forestay??

What sense does that make?

I'm lost here.

Please help with the logic.

A quick education is needed.

- seacatcapt

- Chief Steward

- Posts: 66

- Joined: Mon May 04, 2009 7:51 pm

- Sailboat: MacGregor 26M

- Location: Richland, WA; 2005 26M 70HP Suzuki

Re: Another forestay failure/mast crash

I see where the CDI furler manual calls for toggles at both ends of the headstay, however my '05 M with a CDI furler has the top rigging shown in the earlier photo as well. In thinking about what function the toggle should perform (i.e., allow for movement in two planes), I can't see why the stock rigging (as shown in the photo) doesn't allow for that same movement. So, is a toggle at the top really needed? I know Cheryl at BWY frequents these forums - it would be great if BWY could weigh in on whether a top toggle is needed/required.

- Sumner

- Admiral

- Posts: 2375

- Joined: Sun Jan 04, 2009 3:20 pm

- Sailboat: MacGregor 26S

- Location: SE Utah

- Contact:

Re: Another forestay failure/mast crash

seacatcapt wrote:....I can't see why the stock rigging (as shown in the photo) doesn't allow for that same movement. ..

If you take the forestay and move it say up and down in the picture it will rotate on the shackle pin. If you take and bend the forestay side to side in the picture it can't rotate, but would try and bend just below the thimble and where the first nicopress is located.

I guess it is up to one to decide if the lack of a toggle is the reason for some of the failures or not. Since a toggle and a forestay without a thimble is not that much I would go that route and did.

Personally I'm not crazy about how they also have the top shrouds on the same pin and they are putting a point load on the shackle pin with them as they are rotated at an angle to the pin, but obviously it works. I like the way they have the top shrouds on the S we have, but that means more parts, higher cost and lower profit margin. I'm for sure not a rigging designer, so maybe having all of the loads coming to a common point on the one pin has merit and isn't just a cost saving move.

If you used a toggle like above at the bottom left of the page it could rotate on the pin and the thimble could rotate on it. I used one like that along with a new forestay that has....

.... a swaged on fitting on the top like above at the top left side of the page here....

http://www.riggingonly.com/stdrig04.htm ... 0TERMINALS

They made up the new forestay for us that is now 5/32 at a very reasonable price. Since I was going up to 5/32 I also increased the size of the turnbuckle to 5/16 and all of the pins and toggles to 5/16 and went with a Johnson lever that is also 5/16 and a little longer than most people use with their CDI's.

This resulted in some additional length and I moved the forestay and the new top shrouds that I made up the mast some and still have the original 1/8 inch forestay attached below the furler on the mast. I have a quick lower mounting point for it on the anchor roller mount just behind the one for the furler. I can still run a hank-on sail up on it or have the furler out and a hank-on sail out at the same time. We haven't done that yet, but will at some point. We are also going to get a storm jib that could be run up the inner forestay. The inner while not in use is just bungeed to the mast,

Sum

Our Endeavour 37

Our Trips to Utah, Idaho, Canada, Florida

Our MacGregor S Pages

Mac-Venture Links

-

DaveC426913

- Admiral

- Posts: 1915

- Joined: Mon Jul 14, 2008 8:05 am

- Sailboat: MacGregor 26X

- Location: Toronto Canada

- Contact:

Re: Another forestay failure/mast crash

Well, there's a lot of chatter on this subject, and I'm too much of a novice to sort it out.

Unless someone wants to explain it with large brightly-coloured blocks, I'm going to have to write to my local Mac dealer and ask them about proper tensioning and rigging replacement.

Unless someone wants to explain it with large brightly-coloured blocks, I'm going to have to write to my local Mac dealer and ask them about proper tensioning and rigging replacement.

- parrothead

- First Officer

- Posts: 426

- Joined: Sun Mar 06, 2005 7:25 am

- Sailboat: MacGregor 26M

- Location: Former vessel: '05 M "Blue Heaven" - Nissan 50 TLDI --- Now owner of a Gemini 3400

Re: Another forestay failure/mast crash

Hi Sum,

Thanks for the clear illustrations of the toggle and the forestay end fitting. Looks like a winter project to me -- for now I'll keep my spinnaker halyard clipped to the bow rail as a backup.

As for the coming together of the forestay and the upper shrouds at a common point, . The standing rigging needs to attach to a point that essentially does not move, while the mast pivots back and forth behind it. The attachment point for the lower shrouds is similar.

. The standing rigging needs to attach to a point that essentially does not move, while the mast pivots back and forth behind it. The attachment point for the lower shrouds is similar.

Doug

Thanks for the clear illustrations of the toggle and the forestay end fitting. Looks like a winter project to me -- for now I'll keep my spinnaker halyard clipped to the bow rail as a backup.

As for the coming together of the forestay and the upper shrouds at a common point,

I'm sure that it has to do with the rotating mast on thePersonally I'm not crazy about how they also have the top shrouds on the same pin and they are putting a point load on the shackle pin with them as they are rotated at an angle to the pin, but obviously it works. I like the way they have the top shrouds on the S we have, but that means more parts, higher cost and lower profit margin. I'm for sure not a rigging designer, so maybe having all of the loads coming to a common point on the one pin has merit and isn't just a cost saving move.

Doug

- delevi

- Admiral

- Posts: 2184

- Joined: Fri May 06, 2005 1:03 am

- Location: San Francisco Catalina 380, former 26M owner

- Contact:

Re: Another forestay failure/mast crash

I don't think the issue is with the stock attachment. Probably not even the 1/8 cable, though I would still beef it up. Imagine the genoa flying. Now load it up with the sheet. Everyhting is pulling on the forestay, including the top fitting of the furler foil. If it is pressing close to the nicompress fitting at the top, eventually the wires start to break and/or get severed, or just bend so much they break. I can't stress this enough as it was a personal experience of mine. I didn't have a dismasting but noticed the damage to the cable prior to rigging the boat one time. I promptly replaced it. The damage was in the place I described. BTW, it was a 5/32" cable. Bottom line is to make sure there is ample clearance up there as a nicompress or swage fitting is where most rigging failures happen. A tight forestay will help a lot, both with this issue and with better sailing performance. It is not "unnecessary tension." From a sailing standpoint, there is absolutely no benefit in a loose forestay. There is ample benefit in a tight forestay. Unfortuantely, due to rigging and de-rigging, having the forestay tight is more trouble than most owners want to deal with. One option might be to upgrade the stay adjusters on the upper shrouds to allow for quick and precise tensioning once the mast is up. Regardless of one's desired headstay tension, I think it's a good idea to check how much clearance you have where the top of the cable exits the furler. I'm quite surprised to learn that there were several dismastings on Macs. I guess at the end of the day, things break and sh*t happens. Could happen to anyone on any boat.

fair winds,

Leon

fair winds,

Leon

- Sumner

- Admiral

- Posts: 2375

- Joined: Sun Jan 04, 2009 3:20 pm

- Sailboat: MacGregor 26S

- Location: SE Utah

- Contact:

Re: Another forestay failure/mast crash

I didn't think about the rotating mastparrothead wrote:....I'm sure that it has to do with the rotating mast on thePersonally I'm not crazy about how they also have the top shrouds on the same pin and they are putting a point load on the shackle pin with them as they are rotated at an angle to the pin, but obviously it works. ...... The standing rigging needs to attach to a point that essentially does not move, while the mast pivots back and forth behind it. The attachment point for the lower shrouds is similar. Doug

I'm curious now, so does that bracket pivot itself or is it fixed to the mast and rotates with it? With all of that possibly moving then I would see even more of a need for a toggle up there.

I was going to setup my forestay so that the CDI foil rotated on the swagged on fitting at the top of the forestay, but decided to call them about that. They said that they wanted it rotating on the wire just below the fitting. I did that, but still wonder why?

I set the forestay tension without the furler foil/sail and a loos gauge and marked the turnbuckle and then installed the foil and sail. With the Johnson lever it is very easy to pin the forestay with the same tension each time and without changing where the turnbuckle is screwed to. Also I couldn't pin the forestay as tight as it is now without the Johnson lever unless I backed the turnbuckle way off and that would be a pain with the furler drum. I love the lever.

With the Johnson lever, toggle, drum and such at the bottom, the sail is now high enough to easily see under it. That was something Ruth really didn't like before when she couldn't and now she is a happy camper. The CP might be a little higher, but the mediocre way we sail it has not been a problem.

Now saying that I'm sure the tension is somewhat different with the boat on the water vs. on the trailer. Maybe someday I'll try and check it boat places and compare,

Sum

Our Endeavour 37

Our Trips to Utah, Idaho, Canada, Florida

Our MacGregor S Pages

Mac-Venture Links

- seacatcapt

- Chief Steward

- Posts: 66

- Joined: Mon May 04, 2009 7:51 pm

- Sailboat: MacGregor 26M

- Location: Richland, WA; 2005 26M 70HP Suzuki

Re: Another forestay failure/mast crash

The bracket is fixed to the mast so there is torquing motion on the forestay fittings (particuarly near the shackle) as the mast rotates back and forth on tacks. Ideal setup for fatigue failure.I'm curious now, so does that bracket pivot itself or is it fixed to the mast and rotates with it? With all of that possibly moving then I would see even more of a need for a toggle up there.